PCB antenna material type

Introduction

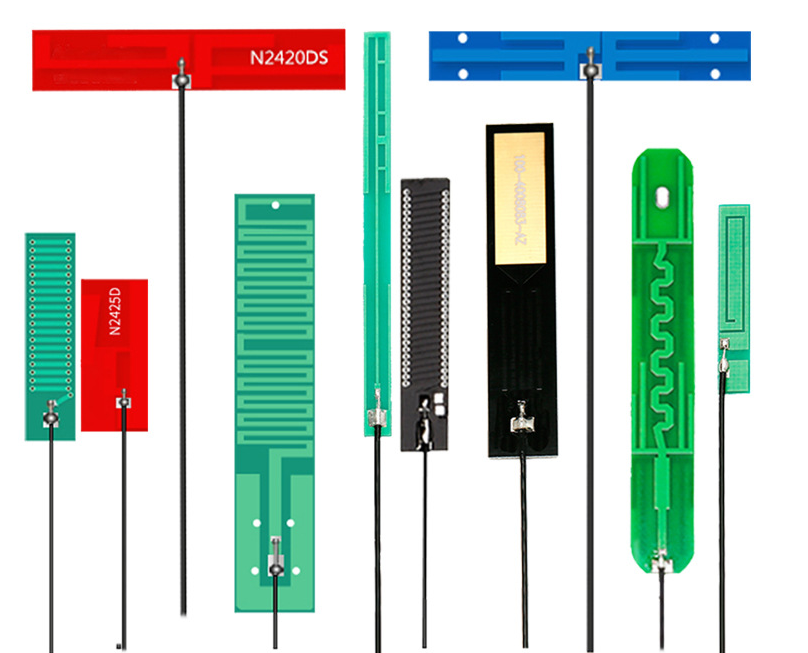

With the increasing demand for wireless communication and the advent of the Internet of Things (IoT), the use of printed circuit board (PCB) antennas has become ubiquitous. PCB antennas provide numerous advantages such as easy integration, low fabrication cost, and reduced system complexity. PCB antennas can also be custom designed to meet specific requirements, making them suitable for a wide range of applications. With the advancement in materials technology, new materials have been developed to improve the performance of PCB antennas. In this paper, we will explore the materials used for PCB antennas and their impact on antenna performance.

Types of PCB antenna materials

The choice of material for a PCB antenna is critical to its performance. Various types of materials are used for PCB antennas depending on the required performance, fabrication cost, and environmental conditions. Some of the common materials used for PCB antennas include:

1. FR4: FR4 is a glass fiber reinforced epoxy laminate, which is commonly used for PCB substrates. It is a low-cost material with a dielectric constant of approximately 4.5, making it suitable for low-frequency applications. However, FR4 has limitations at high frequencies, as its dielectric loss increases with frequency.

2. Rogers: Rogers is a high-performance laminated substrate material with a low dielectric constant and low loss tangent, making it suitable for high-frequency applications. Rogers materials are commonly used in the fabrication of cellular, wifi, and Bluetooth antennas.

3. Ceramic: Ceramic materials offer excellent electrical properties, including a high Q factor, low dielectric constant, and low loss tangent. They are ideal for high-frequency applications, where the antenna size must be kept small. Ceramic materials are commonly used in the fabrication of GPS and satellite antennas.

4. Flexible materials: Flexible materials such as polyimide and liquid crystal polymer offer the advantage of flexibility, enabling the fabrication of conformal and wearable antennas. These materials are also suitable for applications where repeated bending or twisting is required, such as in automotive antennas.

Impact of PCB antenna materials on performance

The choice of materials for a PCB antenna has a significant impact on its performance. The primary performance metrics of a PCB antenna include gain, radiation efficiency, bandwidth, and impedance matching. The choice of materials affects these metrics in different ways.

1. Dielectric constant: The dielectric constant of the substrate material affects the resonant frequency of the antenna. A higher dielectric constant leads to a lower resonant frequency, while a lower dielectric constant leads to a higher resonant frequency. This has implications for the bandwidth of the antenna, as a higher dielectric constant can limit the broadband performance.

2. Loss tangent: The loss tangent of the substrate material affects the radiation efficiency of the antenna. A higher loss tangent leads to a lower radiation efficiency, as some of the energy is lost in the substrate. This has implications for the gain of the antenna, as a lower radiation efficiency leads to a lower gain.

3. Substrate thickness: The substrate thickness affects the impedance matching of the antenna. A thinner substrate leads to a lower impedance, while a thicker substrate leads to a higher impedance. This has implications for the matching network required to achieve optimal impedance matching.

Conclusion

In conclusion, the choice of materials for a PCB antenna is critical to its performance. Various materials are used for PCB antennas, depending on the application requirements, fabrication cost, and environmental conditions. The dielectric constant, loss tangent, and substrate thickness are the key parameters that affect the performance of the antenna. Designers should carefully consider the selection of materials to achieve optimal performance and ensure the desired performance metrics are met. Further research in material science can provide new materials with better performance characteristics, enabling the design of more efficient and reliable PCB antennas.